Collaborative robot welding workstation_2

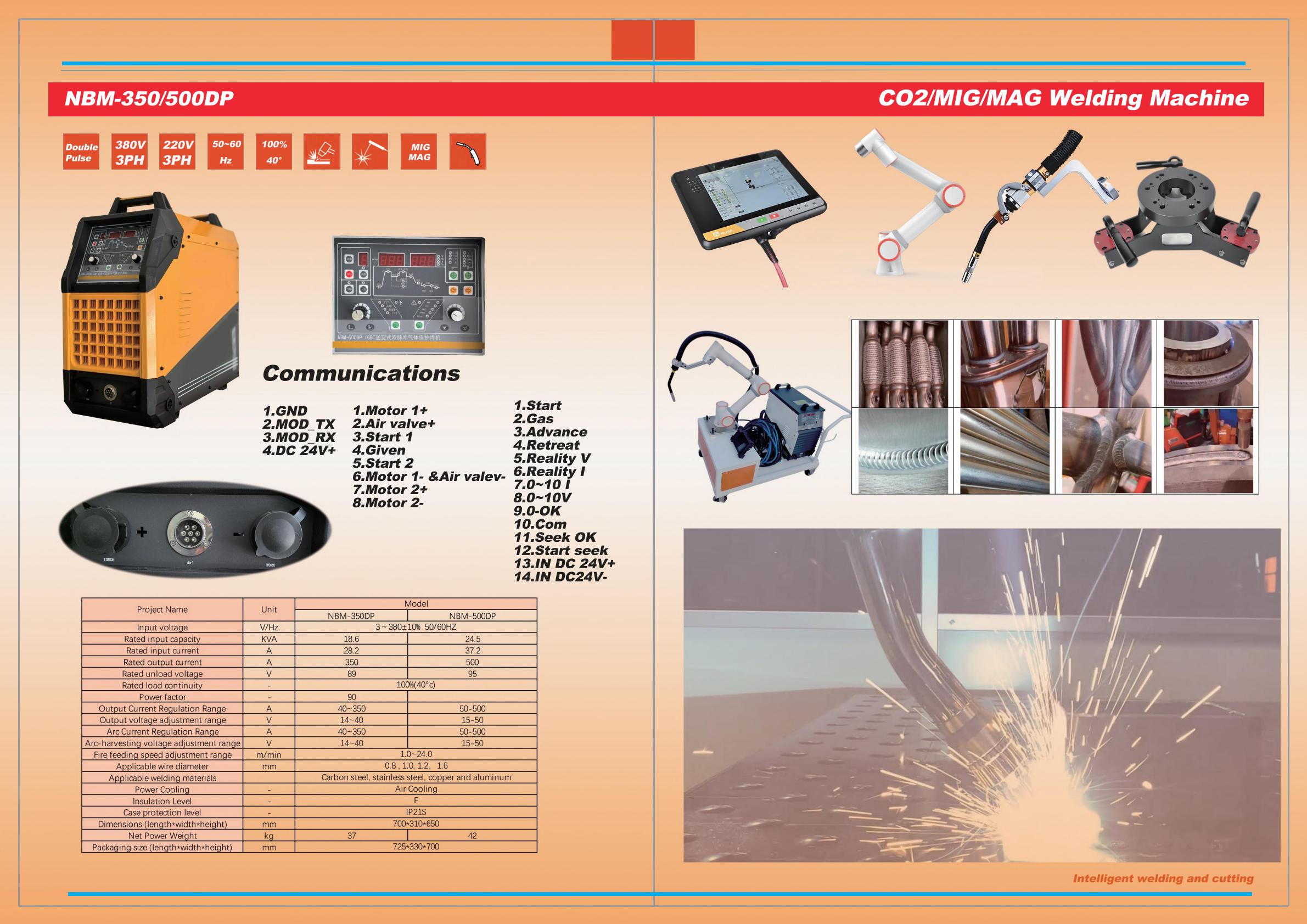

Digital welding machine is an industrial digital welding machine with full digital, 100% load rate, pulse control stability and other characteristics. It is widely used for efficient welding of various materials such as carbon steel, stainless steel and aluminum alloys. With a strong versatile and precise control capability, meet different welding needs, provide stable welding performance, especially suitable for industrial, manufacturing and automated welding applications.

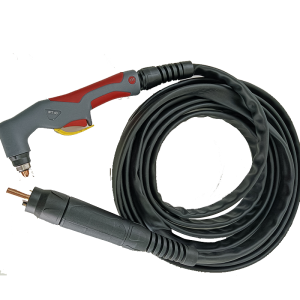

Robot welding guns:

1, exclusive air flow design, effectively protect the conductive mouth, prevent splash, can achieve long-term continuous welding.

2, integrated design, welding speed is fast, high efficiency.

3, suitable for a variety of metal materials (such as carbon steel, stainless steel, aluminum alloy).

4, the welding quality is stable, forming beautiful.

5, match the robot special intelligent wire feeding machine, send the silk accuracy.

Quick Programming Handle:

Smart Tool is an intelligent collaborative robot-assisted component designed for collaborative robots. By integrating advanced functional modules and simple installation, the automation debugging and application of robot end operation can be quickly realized, significantly improving production efficiency.

Software integration: Easily configure communication parameters and functional buttons through the display interface to support the rapid writing and preservation of complex programs.

Precision welding: efficient and stable welding process through ARC instructions and I/O output.

Flexible application: support mobile program teaching, welding process setting and I/O interface call to meet the needs of diverse chemical industry.

Magnetic Suction Base:

In collaborative robot welding, the magnetic suction base is used to achieve the rapid deployment of collaborative robots. When welding large components or requiring robots to move, the robot can be rapidly deployed to the workpiece welding plane or 3D welding platform using magnetic suction base, the product has the following characteristics:

Super adsorption: built in three points magnetic layout, uniform adsorption, strong anti-slip ability.

Quick Installation: No complex tools, i.e. ready to use, 5 seconds to complete the robot fixing.

Durable material: Aviation materials and wear-resistant coating, corrosion resistance, long life protection.

Flexible adaptation: compatible with a variety of robot models, supporting various tasks such as welding, cutting, handling.

Safe release: switch magnet control, easy to disassemble, easy operation and safe.

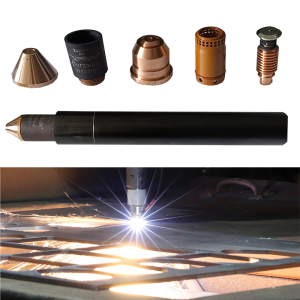

Powercut plasma cnc Plasma cutting machine Hypertherm Torch LGK-45IGBT, LGK-55IGBT, LGK-65IGBT, LGK-85IGBT, LGK-100IGBT, LGK-105IGBT, LGK-120IGBT, LGK-125IGBT, LGK-130IGBT, LGK-151IGBT, LGK-160IGBT, LGK-200IGBT, LGK-260IGBT, LGK-300IGBT, LGK-400IGBT, LGK-500IGBT, LGK-60AM, LGK-80AM, LGK-100AM, LGK-105AM, LGK-125AM, LGK-160AM, LGK-200AM, LGK-200AF, LGK-300AF, LGK-400AF, LGK-500AF, LGK-200AHF, LGK-300AHF, LGK-400AHF, LGK-500AHF, LGK-200AH, LGK-300AH, LGK-400AH, LGK-500AH Max-45AL, Max-55AL, Max-65AL, Max-85AL, Max-100AL, Max-105AL, Max-125AL, Max-151AL misnco Max-200HPR Max-300HPR Max-400HPR