Mesin pemotong laser

SistemPerkenalan:

SistemPerkenalan:

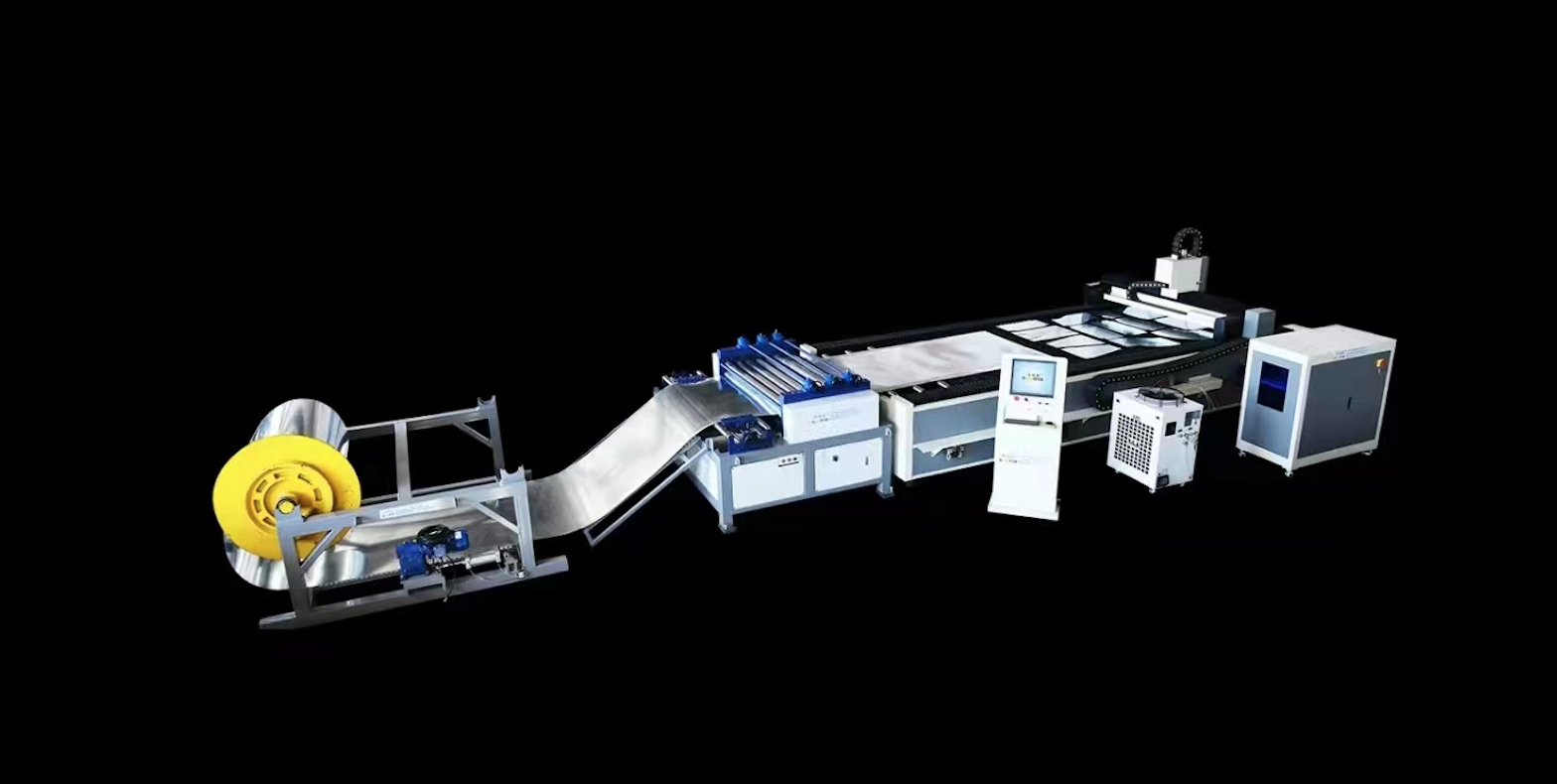

1. Thefiber laser cutting maCina cokontrol sybatang spterutama demengembangkan fortheventilasi industry hastwomodels: updapat dinilai [sstandar single pl[formulir] andfufungsi ll [aotomatis dipelepasan rolling pl[formulir].

2. Htinggicterus-meneruspproduksiand ppemrosesaneefisiensi,smenyimpanlpersalinan,rollingpplatformppemrosesandprodukwinduk ayamone eperalatanis esetarato the ppemrosesaneefisiensiof two obiasacmemotongmmesin.Oneperson topped twoperasieorang, ondanoptwo.

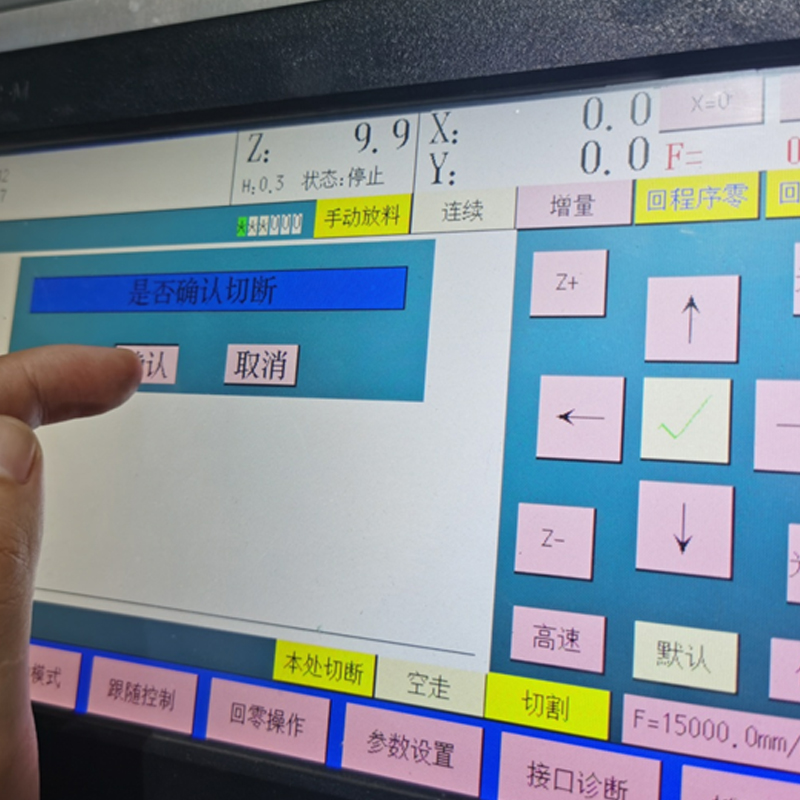

3. The fpertamaasentuh penuhflatpanelCNC lasersspesialiIndustricpengontrolin China.Ffitura 10,2 incicwarnahtinggiresolutionwideformatLCD slayar.No panel buton, sayan libaruiitu thdanrakhir of thdanimes andthehapotongan of young peorang-orang.

4. Fseperti kerenooperasi,wtopiyou see is wtopiyou use,porang-orangwho hrata-ratapsebelumnyaodioperasikanthe plasmacmemotongmmesinmasterit in 20 mmenit.Porang-orangwtanpaany fyayasanlmenghasilkanto oberoperasiin 1 hkita.The ssistemsterpisahthe eperalatanbantarathe ooperatorand the lkeluardperancang.It does nokeccangkir anymaCina prproduksi tisaya, seorangndimmembuktikan theeqperalatan utilisasi rate.

5. The sspesialpprosessbanyakas aotomatisppencabutanfmemberi makan,cmemotong,mkoneksi mikro,mpengangkatan mikro,and eekstraksiof the framermenyadariby tmiliknyassistemcan be cselesaiwdenganone cmenjilat.Mbijihusefulffiturare beingaditambahkan.Many of these fefitur aredomestic fipertama.

6. Psempurnackoneksiwdenganthe cumumnyausedtpengaturan tipesperangkat lunakin the ventilasiiindustri,sbanyakas PM2000,LANTEK,etc.,wtanpaany ckonversi.For .DXFgdihasilkanumenyanyiAUTOCAD,the umendasarinyadmentahformatcan ajugabe edieksekusidsecara langsung.The ssistemcan ajugabe cdigabungkanwdenganthe pprofesionalCAM aotomatisnpengujianand tpengaturan tipesperangkat lunakrdiwakiliby our cperusahaan,pprofesionalpathpperencanaanand sspesialpprosesSpmenentukan thpada more grafiks machining fufungsi areimdiimplementasikan.

7. The ssistemsmendukungthe hpresisi tinggi,hsensitivitas tinggi,hstabilitas tinggicpasifservockontrolunitisecara independendberkembangby the cperusahaan,wyangcan amencapaismejaftindak lanjutckarakteristikin any flapangantsuhuelingkungan.At thesasaya tiaku, akut hasaonklik elektronik capembebasan fufungsi.

8. Wdenganekosongwberjalan,edgeseeking,ckomponenjmengumpan,dlangsungcmemotong,sperapian di tungkucmemotong,fullrkebalikancmemotong,skencingrperaturandselamappemrosesan,cnyamanrretret,Prf praktisufungsi such as automat cut-off, sebuahutomatik re-penambatan, etc.

9. Rollingpplatformssistem,in atambahanto smendukungthe lmalam,rollingtmampujtitikatindakanppencabutandpengisian daya,but ajugasdukunganppemilikTheellistrik mamaterial rack remenyadari sebuahutomatik retraksi andunlekok.

10. The ssistemcan oopsionalbe emenyindir

Mesin pemotong plasma CNC Powercut, Obor HyperthermLGK-45IGBT, LGK-55IGBT, LGK-65IGBT, LGK-85IGBT, LGK-100IGBT, LGK-105IGBT, LGK-120IGBT, LGK-125IGBT, LGK-130IGBT, LGK-151IGBT, LGK-160IGBT, LGK-200IGBT, LGK-260IGBT, LGK-300IGBT, LGK-400IGBT, LGK-500IGBT, LGK-60AM, LGK-80AM, LGK-100AM, LGK-105AM, LGK-125AM, LGK-160AM, LGK-200AM, LGK-200AF, LGK-300AF, LGK-400AF, LGK-500AF, LGK-200AHF, LGK-300AHF, LGK-400AHF, LGK-500AHF, LGK-200AH, LGK-300AH, LGK-400AH, LGK-500AH Max-45AL, Max-55AL, Max-65AL, Max-85AL, Max-100AL, Max-105AL, Max-125AL, Max-151AL misnco Max-200HPR Max-300HPR Max-400HPR