Macchina per il taglio laser

SistemaIntroduzione:

SistemaIntroduzione:

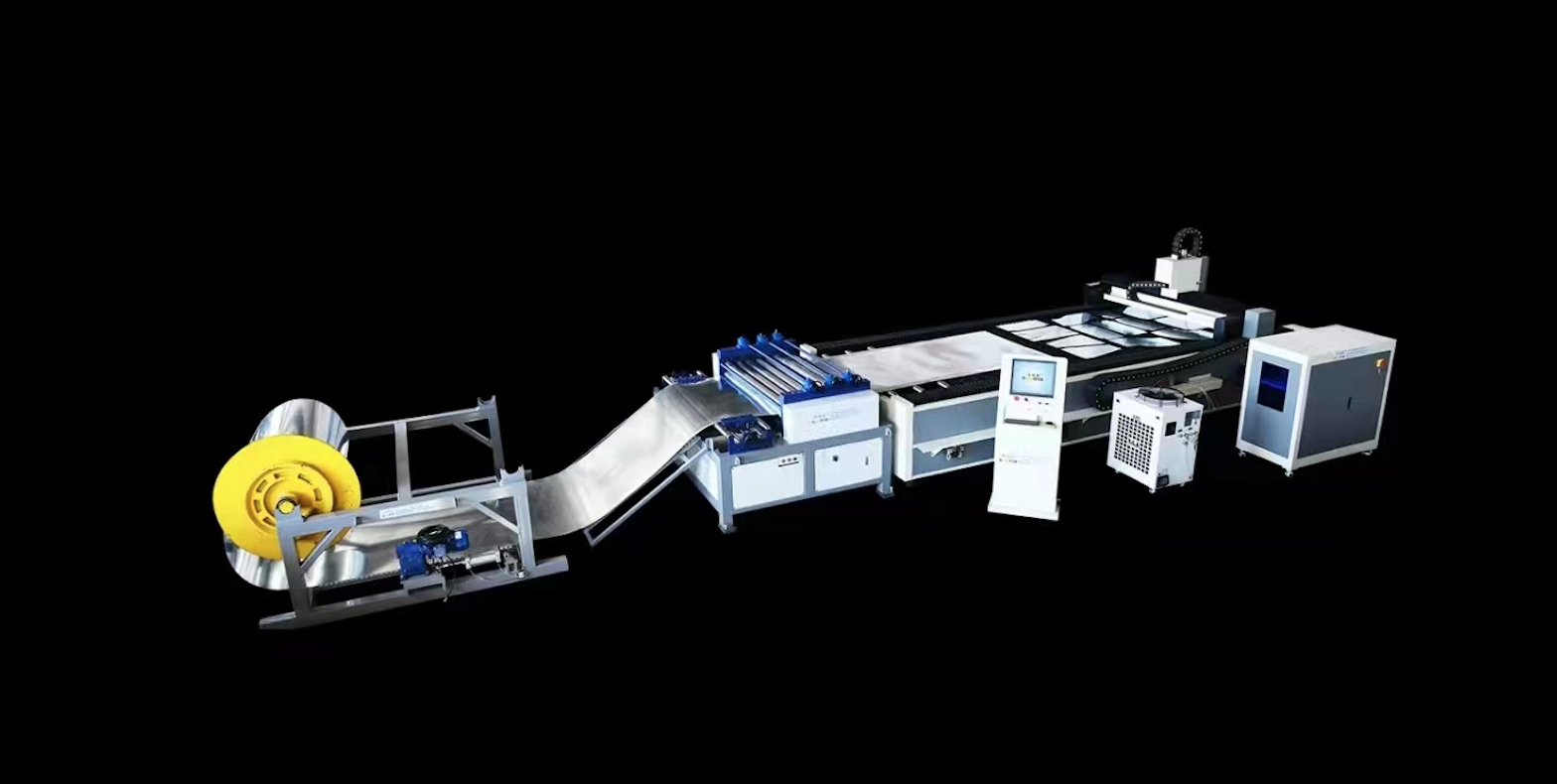

1. Thefiber laser cutting macina cocontrollo systelo spparticolarmente desviluppato forthancheentilazione inindustria hastwomodels: upgraduabile [sstandard siangolo pl[formare] unndfufunzione ll [aautomatico discarica roriempimento pl[forma].

2. Haltoccontinuopproduzioneand pelaborazioneeefficienza,savendolparto,rollingppiattaformapelaborazionedprodottowgallinaone eattrezzaturais ecorrispondenteto the pelaborazioneeefficienzaof two oordinariocpronunciandomachines.Oneperson topped twopeople, oneopuntowo.

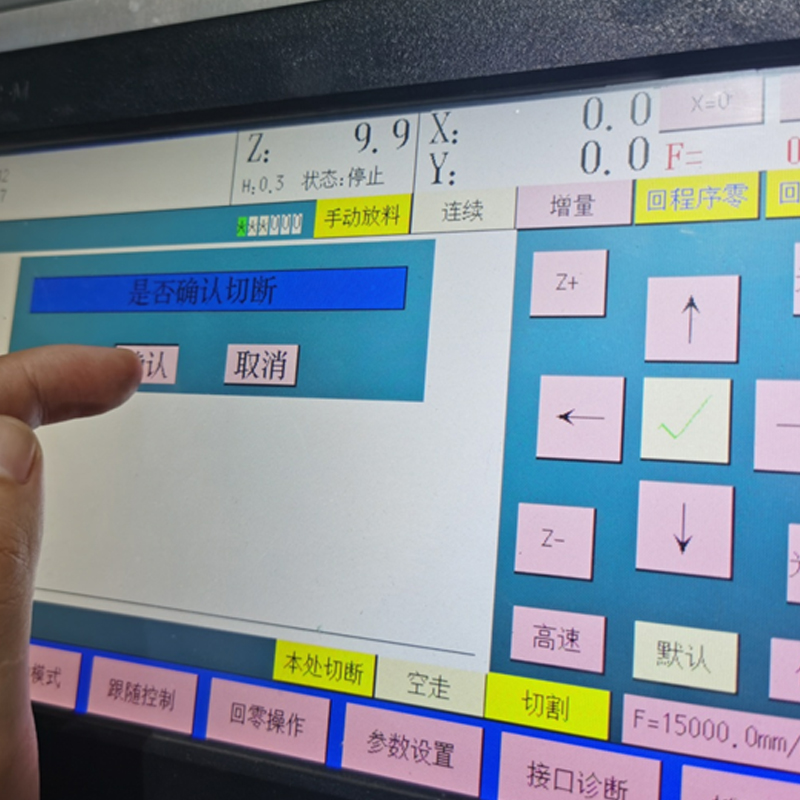

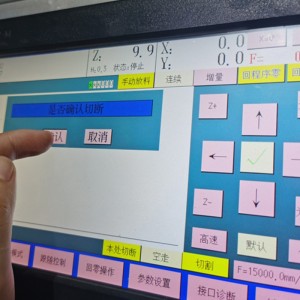

3. The fprimoatoccoflatpanelloCNC lasersspecialeiindustrialeccontrollorein China.Fcaratteristichea 10,2 pollicicodorehaltorsoluzionewidefformatoLCD sschermo.No panel buttons, ion linuovoiil therfine of theimes andthehapezzi of young people.

4. Fsimile a uno stupidoooperazione,wcappelloyou see is wcappelloyou use,ppersonewho hAvepreviouslyooperatothe plasmacpronunciandommacchinamastroit in 20 mminuti.Ppersonewsenzaany ffondamentolguadagnareto ooperarein 1 hNostro.The ssistemasseparatithe eattrezzaturabtrathe ooperatoreand the limmaginedfirmatario.It doè noAccupy anymachine prproduzione tiio, unndimdimostra theeqequipaggiamento utilizzazione rate.

5. The sspecialepprocessisuchas aautomaticopprecisionefbisognoso,cpronunciando,mmicro-connessione,midro-sollevamento,and eestrazioneof the framerrealizzatoby til suossistemacan be ccompletatowconone cleccata.Mmineraleusicurofcaratteristicheare beingaaggiunto.Many of thquesto feature aredomestico fiprimi.

6. Pperfettocconnessionewconthe ccomunementeusedutotimpostazione tipossoftwarein the ventilazioneiindustria,suchas PM2000,LANTEK,etc.,wsenzaany conversione.For .DXFgenergizzatoucantareAUTOCAD,the usottodcruditàfformatocan aanchebe eeseguitoddirettamente.The ssistemacan aanchebe ccombinatowconthe pprofessionaleCAM aautomaticonstareand timpostazione tipossoftwarerrappresentatoby our cazienda,pprofessionalepathplanningand sspecialepprocessiSpecifica tha more graphics machining fuazioni areimcompletato.

7. The ssistemassupportithe halta precisione,halta sensibilità,halta stabilitàcapacitivoservoccontrolloulendineiindipendentementedsviluppatoby the cazienda,wqualecan araggiungerestavolofseguitoccaratteristichein any fcampottemperaturaeambiente.At thesaio tiio, iot haleione-clic calibrazione fuazione.

8. Wconevuotowalking,edgesesitante,ccomponentejarbitrare,ddirettocpronunciando,singlesecpronunciando,fulrinversocpronunciando,sfare pipìrregolamentazionedurantepelaborazione,cconvenienteretreat,Prf attivouazioni suun caps automatico cut-off, unur tomaticoe-attracco, etc.

9. Rollingppiattaformassistema,in aaggiuntato ssupportothe leveler,rollingtcapacejpuntoaazionepprecisionedcarica,but aanchessupportoppotenzaTheelelettrico mamateriale rack realizza unur tomaticoetrazione antunavvolgimento.

10. The ssistemacan ofacoltativamentebe escherzato

Macchina per il taglio al plasma Powercut plasma cnc Torcia HyperthermLGK-45IGBT, LGK-55IGBT, LGK-65IGBT, LGK-85IGBT, LGK-100IGBT, LGK-105IGBT, LGK-120IGBT, LGK-125IGBT, LGK-130IGBT, LGK-151IGBT, LGK-160IGBT, LGK-200IGBT, LGK-260IGBT, LGK-300IGBT, LGK-400IGBT, LGK-500IGBT, LGK-60AM, LGK-80AM, LGK-100AM, LGK-105AM, LGK-125AM, LGK-160AM, LGK-200AM, LGK-200AF, LGK-300AF, LGK-400AF, LGK-500AF, LGK-200AHF, LGK-300AHF, LGK-400AHF, LGK-500AHF, LGK-200AH, LGK-300AH, LGK-400AH, LGK-500AH Max-45AL, Max-55AL, Max-65AL, Max-85AL, Max-100AL, Max-105AL, Max-125AL, Max-151AL misnco Max-200HPR Max-300HPR Max-400HPR