Sebaka sa mosebetsi sa ho tjheseletsa liroboto se kopanetsoeng

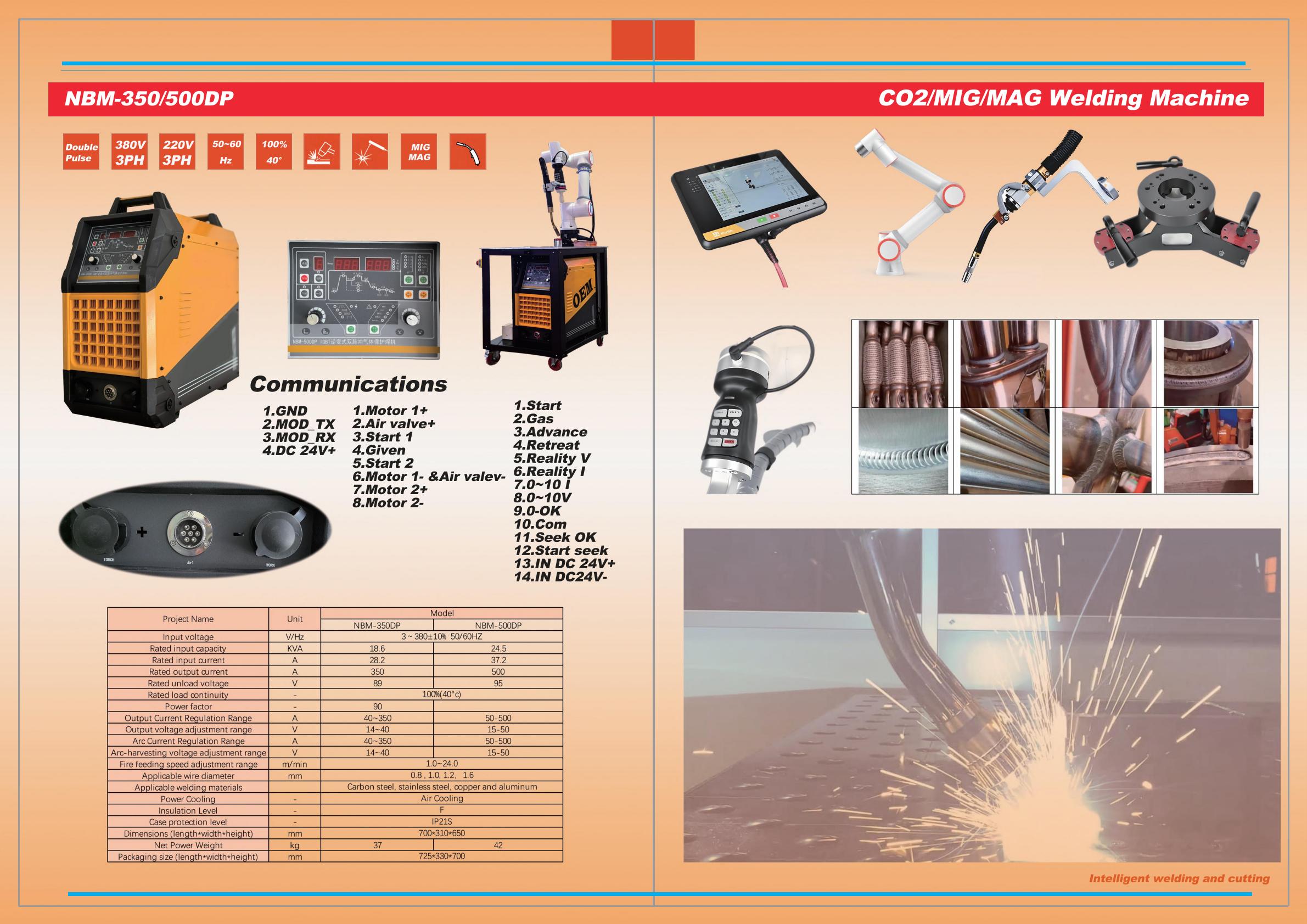

Mochini oa ho tjheseletsa oa dijithale ke mochini oa ho tjheseletsa oa dijithale oa indasteri o nang le sekhahla se felletseng sa mojaro sa dijithale, 100%, botsitso ba taolo ea pulse le litšobotsi tse ling. O sebelisoa haholo bakeng sa ho tjheseletsa ka katleho thepa e fapaneng joalo ka tšepe ea khabone, tšepe e sa ruseng le li-alloy tsa aluminium. Ka bokhoni bo matla ba taolo bo feto-fetohang le bo nepahetseng, bo fihlela litlhoko tse fapaneng tsa ho tjheseletsa, bo fana ka ts'ebetso e tsitsitseng ea ho tjheseletsa, haholo-holo e loketseng lits'ebetso tsa indasteri, tlhahiso le tsa ho tjheseletsa tse iketsang.

Lithunya tsa ho tjheseletsa tsa liroboto:

1, moralo o ikhethileng oa phallo ea moea, o sireletsa molomo o tsamaisang moea ka katleho, o thibela ho phatloha ha metsi, o ka fihlela ho tjheseletsa ho tsoelang pele ha nako e telele.

2, moralo o kopaneng, lebelo la ho tjheseletsa le potlakile, le sebetsa hantle haholo.

3, e loketse mefuta e fapaneng ya thepa ya tshepe (jwalo ka tshepe ya khabone, tshepe e sa ruseng, motswako wa aluminium).

4, boleng ba ho tjheseletsa bo tsitsitse, bo etsa botle.

5, bapisa mochini o khethehileng oa roboto o bohlale oa ho fepa terata, romella ho nepahala ha silika.

Mokgwa wa ho Etsa Lenaneo ka Potlako:

Smart Tool ke karolo e bohlale e thusang roboto ka tšebelisano-'moho e etselitsoeng liroboto tse sebelisanang. Ka ho kopanya li-module tse sebetsang hantle le ho kenya habonolo, ho lokisa liphoso tsa othomathike le ts'ebeliso ea ts'ebetso ea pheletso ea roboto ho ka bonoa kapele, ho ntlafatsa katleho ea tlhahiso haholo.

Ho kopanngoa ha software: Lokisa habonolo liparamente tsa puisano le likonopo tse sebetsang ka har'a sebopeho sa ponts'o ho tšehetsa mongolo o potlakileng le poloko ea mananeo a rarahaneng.

Ho tjheseletsa ka nepo: tshebetso e sebetsang hantle le e tsitsitseng ya ho tjheseletsa ka ditaelo tsa ARC le tlhahiso ya I/O.

Tšebeliso e tenyetsehang: tšehetsa thuto ea lenaneo la mehala ea thekeng, ho beha ts'ebetso ea ho tjheseletsa le mohala oa sebopeho sa I/O ho fihlela litlhoko tsa indasteri e fapaneng ea lik'hemik'hale.

Motheo oa ho Sutla oa Magnetic:

Ho tjheseletsa diroboto ka kopanelo, setsi sa ho hula sa makenete se sebediswa ho fihlella ho kenngwa kapele ha diroboto ka kopanelo. Ha ho tjheseletsa dikarolo tse kgolo kapa ho hloka hore diroboto di tsamaye, roboto e ka kenngwa kapele sefofaneng sa ho tjheseletsa sa mosebetsi kapa sethaleng sa ho tjheseletsa sa 3D ho sebediswa setsi sa ho hula sa makenete, sehlahiswa se na le dibopeho tse latelang:

Ho monya metsi haholo: sebopeho sa makenete se hahiloeng ka lintlha tse tharo, ho monya metsi ka mokhoa o ts'oanang, bokhoni bo matla ba ho thibela ho thella.

Ho kenya ka Potlako: Ha ho na lisebelisoa tse rarahaneng, ke hore, li se li loketse ho sebelisoa, metsotsoana e 5 ho qeta ho lokisa roboto.

Thepa e tšoarellang: Thepa ea lifofane le sekoahelo se sa tsofaleng, ho hanyetsa mafome, tšireletso ea nako e telele.

Ho ikamahanya le maemo ho tenyetseha: ho lumellana le mefuta e fapaneng ea liroboto, ho tšehetsa mesebetsi e fapaneng e kang ho tjheseletsa, ho seha, le ho sebetsana le tsona.

Ho lokolloa ka mokhoa o sireletsehileng: taolo ea makenete ea switch, ho bonolo ho e qhaqha, ts'ebetso e bonolo le e sireletsehileng.

Mochini oa ho seha oa plasma cnc oa Powercut PlasmaLGK-45IGBT, LGK-55GBT, LGK-65GBT, LGK-85GBT, LGK-100IGBT, LGK-105GBT, LGK-120GBT, LGK-125GBT, LGK-130GBT, LGK-151IGBT, LGK-160IGBT0GBT,6KBT0IGBT0 LGK-300IGBT, LGK-400IGBT, LGK-500IGBT, LGK-60AM, LGK-80AM, LGK-100AM, LGK-105AM, LGK-125AM, LGK-160AM, LGK-200AM, LGK-200AF, LGK-300AF0AF0AF0AF0AF0AF0AF0AF0AF0AF0AF0AF0AF0, LGK-200AHF, LGK-300AHF, LGK-400AHF, LGK-500AHF, LGK-200AH, LGK-300AH, LGK-400AH, LGK-500AH Max-45AL, Max-55AL, Max-65AL, Max-85AL, Max-100AL, Max-105AL, Max-125AL0 Max-HP5AL0 misncoR2HP5AL0 Max-HP5AL0 Max-HP5 Max-400HPR