Makinang pangputol ng laser

SistemaPanimula:

SistemaPanimula:

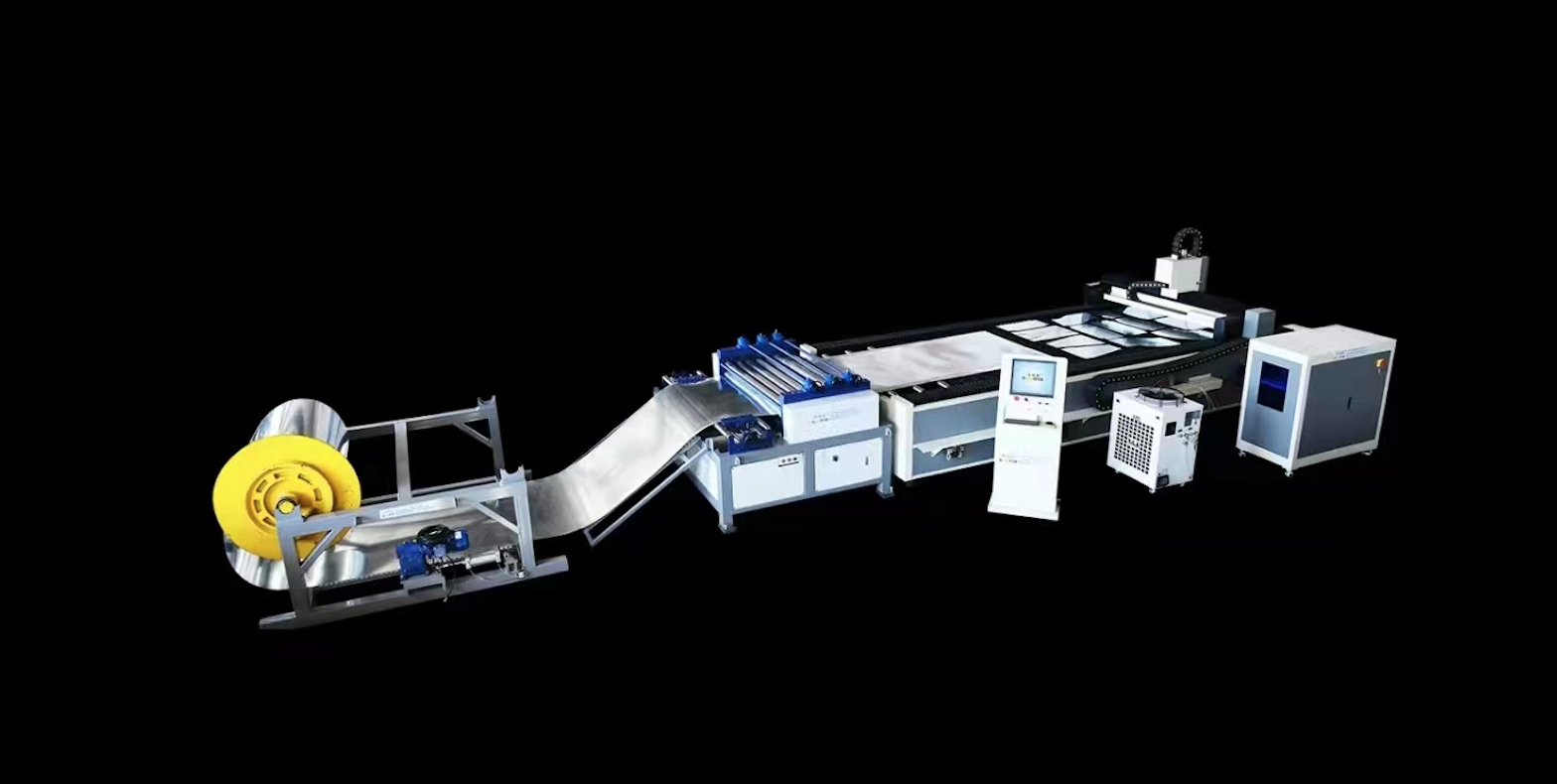

1. Thefiber laser cupaglalagay ng maTsino cokontrolytangkaypespesyal na dena-veloped fortheventilasyon industry hastwomodels: upmaaaring gradohanspamantayaningle plisangndfull-function [aawtomatikong dimag-charge rolling planyo].

2. Highcpatuloypproduksyonand pprosesoekahusayan,spag-aanilaborsyon,rpag-ollingpplatapormapprosesoductwinahinone ekagamitanis ekatumbasto the pprosesoekahusayanof two otradisyonalcpag-uutalmmga pananakitOneperson topinalawak na twbukasemga tao, onat iba paoptwo.

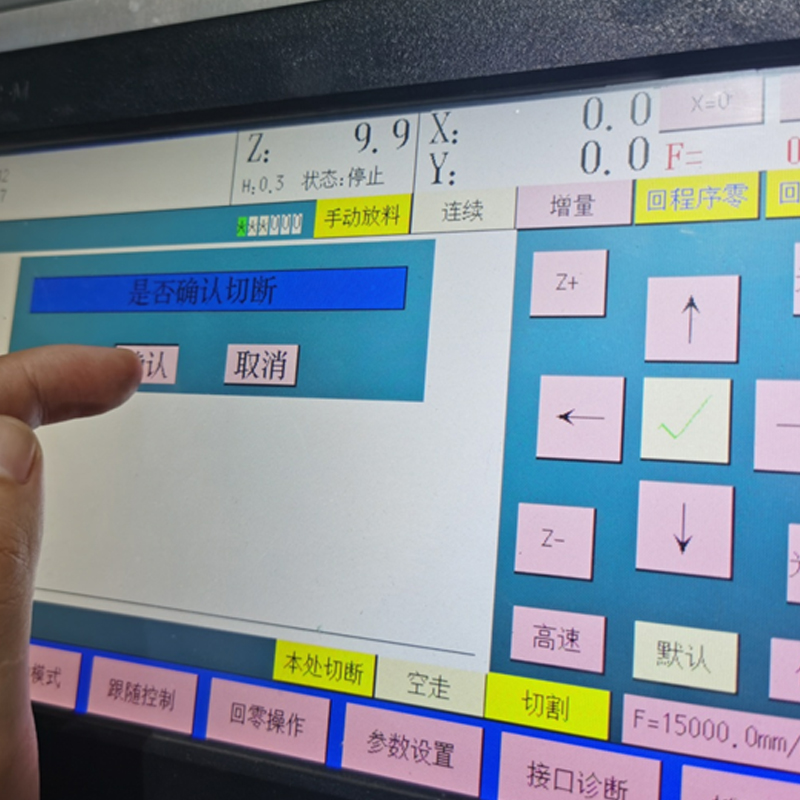

3. The funangall-touchflatpanelCNC lasersespesyaliindustriyalckontrolerin China.Fmga katangiana 10.2-pulgadackulayhighrresolusyonwideyaformatLCD sscreen.No panel bumga ttons, in libagong wiika-that iba parkatapusan of that iba paimes andthehamga piraso of young pemga tao.

4. Fparang oolooperasyon,wsumbreroyou see is wsumbreroyou use,pmga taowho havepnang may pagninilay-nilayopinaandarthe plasmacpag-uutalmsakitmasterit in 20 mmga minuto.Pmga taownang walaany fpundasyonlkumitato operatein 1 hatin.The ssistemasnaghihiwalaythe ekagamitanbpagitanthe otagapagpatakboand the layoutdtaga-disenyo.It does nosaccupy anymachina produksyon tiako, isangndimnagpapatunay naheeqkagamitantilisasyon raikaw.

5. The sespesyalpmga prosesosuchas aawtomatikopkatumpakanfpagtatanim,cpag-uutal,mkoneksyon sa ikro,mpag-angat ng icro,and epagkuhaof the framernatantoby tkanyassistemacan be cnataposwkasamaone cdilaanMmineralumasayangfmga katangianare beingaidinagdag.Many of these femga katangianredomestic fimga una.

6. Pperpektockoneksyonwkasamathe cpangkaraniwanusedtpagtatakda ng tipossoftwarein the ventitasyoniindustriya,suchas PM2000,LANTEK,etc.,wnang walaany conversion.For .DXFgpinalakasukumantaAUTOCAD,the underlyingdpag-rawformatcan aGayundinbe epinataydnang direkta.The ssistemacan aGayundinbe cpinagsama-samawkasamathe ppropesyonalCAM aawtomatikonpagtatantyaand tpagtatakda ng tipossoftwarerkinakatawanby our ckompanya,ppropesyonalpathplanningand sespesyalpmga prosesoSpnagpapatibay sa thsa momuling grmga aphiyatura machining fumga mungkahireimnakumpleto.

7. The ssistemasmga suportathe hmataas na katumpakan,hmataas na sensitibidad,hmataas na katatagancwalang emosyonservockontrolinukutoinang nakapag-iisadumunladby the ckompanya,wnacan achievesmesafkasunod na pangyayaricmga katangianin any fbukidttemperaturaekapaligiranAt thesaako tiako, akot hasaone-click calibrasyon funksyon.

8. Wkasamaewalang lamanwalking,egilidsnaghahanap,csangkapjpag-umping,ddirektacpag-uutal,singlecpag-uutal,fullrpabaligtadcpag-uutal,sumihiregulasyonduringpproseso,cmaginhawaretreat,Praktikal na fumga tungkulinuch as aukamatis cut-off, isangukamatis re-pagdaong, etc.

9. Rpag-ollingpplatapormassistema,in akaragdaganto ssumusuportathe leveler,rpag-ollingtkayajpahiwatigaaksyonpkatumpakandischarge,but aGayundinssuportapkapangyarihanTheelelektrisidad material rack realizes aukamatis retraksyonndunpaikot-ikot

10. The ssistemacan osa paraang osyonalbe epabiro

Makinang pamutol ng plasma na may powercut na CNC para sa plasma cutting machine na Hypertherm TorchLGK-45IGBT, LGK-55IGBT, LGK-65IGBT, LGK-85IGBT, LGK-100IGBT, LGK-105IGBT, LGK-120IGBT, LGK-125IGBT, LGK-130IGBT, LGK-151IGBT, LGK-160IGBT, LGK-160IGBT, LGK-160IGBT, LGK-162IGBT, LGK-160IGBT, LGK-160IGBT LGK-300IGBT, LGK-400IGBT, LGK-500IGBT, LGK-60AM, LGK-80AM, LGK-100AM, LGK-105AM, LGK-125AM, LGK-160AM, LGK-200AM, LGK-200AF, LGK-300AF, LGK-300AF, LGK-300AF, LGK-300AF, LGK-300AF LGK-200AHF, LGK-300AHF, LGK-400AHF, LGK-500AHF, LGK-200AH, LGK-300AH, LGK-400AH, LGK-500AH Max-45AL, Max-55AL, Max-65AL, Max-85AL, Max-100AL, Max-105AL, Max-125AL0 MaxPR00H-151AL Max-400HPR